Food Safety Budget….Often, food safety professionals struggle to secure the resources needed to guarantee food safety in their organizations. The current corona-virus pandemic makes the food safety professionals’ mission even more complicated. The current situation will last for several more months (if not longer) for sure.

How can we elevate awareness to the importance of food safety inside our organization, even in challenging times like these?

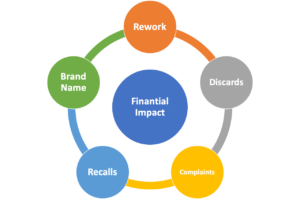

We can elevate awareness from two distinct perspectives: working on the culture and showing numbers. Of course, the presence of the sound “food safety culture” is significant, but in this article, we focus our attention on 5 tips that will demonstrate to Top Management that food safety is a sound investment!

The main question that arises is how do you get real financial numbers linked to Food Safety aspects? The difficult way of doing this is to work diligently with your financial colleagues and establish what is called an “activity-based costing approach”. This approach takes a lot of time and may cost more than the potential savings which can be generated with the resulting financial action plan insights.

One way to make your effort more effective, is to translate the consequences of the inability to guarantee Food Safety into financial numbers in a simple manner. In this article, we will present to you 5 areas where you can create a “translation” of operational performance metrics into a financial value. You can then use the insights at the financial level to discuss the importance of food safety with senior management. Moreover, you will even be able to perform a cost-benefit analysis on potential improvement efforts in relation to food safety.

1- Rework and Food Safety Budget

In most food manufacturing plants, not every batch of product is right the first time. There is a wide range of small errors that can be made which require the product to be reprocessed or reworked. A few examples of these situations are the use of wrong packaging material, faulty batch code on the product, insufficient heat treatment of the product, the presence of a foreign object which is detected during QC testing or metal detection.

Every time product needs to be reworked, there are costs incurred in terms of additional labour costs and / or additional (raw / packaging) material costs. A good way to obtain insight into the costs involved in rework is to create a Pareto-chart of the rework over a period of a year. For each column in the Pareto-chart you can estimate the additional labour and material costs per kg of rework, just by discussion with the head of production and the purchasing team.

Once you have an average cost per kg of rework in different classes, you can use the amounts of rework to monitor the monetary impact of rework on your organization.

2- Product Discards

If products are found not to be OK and reworking these products is not feasible, the only option that remains is to discard the product. In doing so, the entire value of the product also is

If products are found not to be OK and reworking these products is not feasible, the only option that remains is to discard the product. In doing so, the entire value of the product also is

destroyed. Simply by setting a simple system to measure the weight of all product wasted and then multiplying it with the average cost price, you will get a near accurate estimation of the monetary impact of product waste.

In some countries you will have to pay for the food waste to be processed, this then adds to the cost of food waste in your organization. For some products, the waste stream might still be worth some money by sending into the animal feed chain or creating energy via bio fermentation.

Depending on the local situation in terms of national regulations, it might be an option to still reclaim a part of the value of the product by “degrading” it to animal feed. In most countries however, there are strict rules one must obey when sending food stuff back into the feed / food chain.

Bio fermentation is a good alternative for quite a few food related waste streams. Especially liquid streams and bulk food streams that only contain food stuff (i.e. no packaging materials) can often be effectively bio fermented. Some countries even have a positive taxation policy towards bio fermentation, which might result in more money for the waste.

It goes without saying that food waste prevention should always remain a priority.

3 – Complaints and Food Safety Budget

Looking broadly at complaints, you can picture there are two classes of complaints: “normal” complaints (e.g. dents in packaging, colour deviations of the product) and food safety related complaints (e.g. spoilage, gas formation or consumer food-borne illness). Food safety related complaints take more time (and money) to be investigated than “normal” complaints.

Rather than focusing on the cost of each individual complaint, it is proposed to look at the total number of complaints in an entire year. By adding up all the costs in relation to the complaints (e.g. hours spent by QA and QC), external laboratory service costs, consequential audits, customer visits, reimbursements, re-shipping of product) and dividing these costs by the number of complaints in each category, you can calculate an average cost per “normal” complaint and per food safety related complaint.

Once you have these average costs in place, you can simply monitor the number of complaints to get a sense of the total costs to the organization. Furthermore, if you start defining improvement projects to prevent certain complaints, you can even make a cost-benefit analysis for each improvement project.

4- Recalls

One of the worst things to happen to a food manufacturing company is a recall. While executives largely still think that a recall will never happen, it is a question of when and not if a recall will happen. On average every company faces a recall situation once every 5 to 10 years. Of course, some companies are more prone to recalls than others, especially those companies producing highly complex formulated food stuff containing allergens are very much prone to recalls.

One of the worst things to happen to a food manufacturing company is a recall. While executives largely still think that a recall will never happen, it is a question of when and not if a recall will happen. On average every company faces a recall situation once every 5 to 10 years. Of course, some companies are more prone to recalls than others, especially those companies producing highly complex formulated food stuff containing allergens are very much prone to recalls.

There is no “typical” cost of a recall, as this depends on many factors. Still, we will give you some direction in this article.

If we start off with the sales value of the products involved in a recall (typically your customer will require you to take the product back and reimburse them in full for it). On top of this you will find yourself transporting products back to your premises and re-shipping new products (oftentimes for free). This brings the value of a recall already to twice the sales value of the products involved.

In most cases, a recall is performed because of a food safety concern. Before commencing a recall, you want to be (close to) 100% sure that it is indeed a food safety concern, hence you will perform a deep analysis of the issue(s) at hand. This will often involve the use of external laboratory services and a larger than normal number of samples to be analysed. For simplicity’s sake, we attribute once more a total cost of the sales value of the products involved for analysis of the issue.

A recall situation oftentimes will result in consequential audits. If your company is certified against a GFSI benchmark standard, it is likely your Certification Body will require an additional audit. The same holds true for the customer(s) involved in the recall. So, this will add another cost at the level of the sales value of the products involved and should be taken into account of your Food Safety Budget.

All in all, you can say that the minimum cost of a recall to a company easily equates to 4 times the sales value of the products involved. While this is more likely an underestimation of the cost involved it is a good base number to work with.

5- Brand Name Value Reputation Damage

In today’s world news travels at the speed of light. If consumers find your products are not meeting specific expectations, or even worse if consumers get seriously ill or die after consuming your products, this will have a major impact on your brand.

When consumers lose faith in a brand – this has a long-term impact. In the past, several examples of big consumer brands caused death or severe bodily harm to consumers. The market share of these brands collapsed in all cases and it took them at least 10 years to return to the same level of sales as before the issue(s) arose.

The best way to determine the potential impact of reputation damage is to look at the entire product portfolio of your company and take the sales value of the biggest product (or brand) of your company. Take 90% of the value of this number and you will have a pretty accurate estimate of the financial impact of bad press on this product in case of a severe food safety issue.

You might argue that this is never going to happen to your company – but consider this example… In 2011 there was an E. coli outbreak in Europe which was wrongfully blamed on cucumbers. This resulted in the destruction of the entire crop of cucumbers from Spain. In the end it turned out it had nothing to do with the cucumbers, but the outbreak was caused by fenugreek seeds imported from Egypt in 2009 and 2010 which were used to grown bean sprouts in Germany.

The example demonstrates that reputation costs in relation to food safety might realistically occur, even when your company has nothing to do with it! Also an aspect to take into consideration into your Food Safety Budget…

Conclusion

If we ask Food Safety Professionals what is the most difficult aspect of their job, the large majority won’t talk about technical issues but probably about the ability to “bring other people on board”. How to persuade people in an organization that Food Safety relies a lot on simple (no/low cost) behaviours but also on financial resources that should be made available?How to make sure you get a Food Safety Budget?

If we ask Food Safety Professionals what is the most difficult aspect of their job, the large majority won’t talk about technical issues but probably about the ability to “bring other people on board”. How to persuade people in an organization that Food Safety relies a lot on simple (no/low cost) behaviours but also on financial resources that should be made available?How to make sure you get a Food Safety Budget?

In the long term, the low-cost and most effective way to increase awareness on the importance of Food Safety is building a Food Safety Culture. For this Food Safety Professionals must be prepared to endure a journey where every day they shall explain people that lack of food safety leads to disease or death and to show how their specific tasks impact food safety. Along this journey, Food Safety Professionals and Top Management should responsibly “walk the talk” and be held accountable.

Parallel to that, Food Safety Professionals should monetise (spell out in numbers) the consequences of the inability to guarantee Food Safety as much as possible. This is where the 5 tips presented in this article can contribute (with the supplemental PDF file developed to support it). The best place and time to do this is while managing organizational risks. Using the information collected in the PDF file, Food Safety Professionals should make the point that Food Safety (or better, the inability to guarantee Food Safety) is an organizational risk and probably one of the most significant food business risk to address. A strong way to get the attention of top management is to talk their language: financial impact.

In times of crises, as the current COVID-19 pandemic, where generally businesses have a more restrictive outlook when allocating resources, the key to sustaining Food Safety budgets is to work on both sides the equation. Building the long-term Food Safety Culture and assure that Top Management recognize, today, Food Safety as a cornerstone in the food business’ future profitability.

Want to have the best support ever?

As a quality & food safety professional, you always have times when you think: “I would like to discuss this with an expert.” Or you wonder how best to tackle a difficult problem and would like to discuss this with an experienced person.

Food Safety Experts’ QFS Success Coaching gives you unlimited access to our experts for a year, when you need it.

Interested? Click here ! Or see : https://foodsafety-university.thinkific.com/courses/qfs-success-coaching

Interesting blogs to read:

What Skills Does a Quality Manager Need?

7 Steps to be IMPACTFUL as a Quality Manager

Other Interesting Programs of Food Safety Experts:

Replay Workshop Effectively Upgrade Your Quality and Food Safety Management System to a Higher Level